Sweep frequency response analyzer-SFRA

Sweep frequency response analyzer-SFRA Specification

- Usage

- Industrial

- Size

- Standard Sizes

- Material

- MS

- Power Supply

- Manual

- Color

- Black

- Display Type

- Analog Only

Sweep frequency response analyzer-SFRA Trade Information

- Minimum Order Quantity

- 1 Unit

- Delivery Time

- 30 Days

About Sweep frequency response analyzer-SFRA

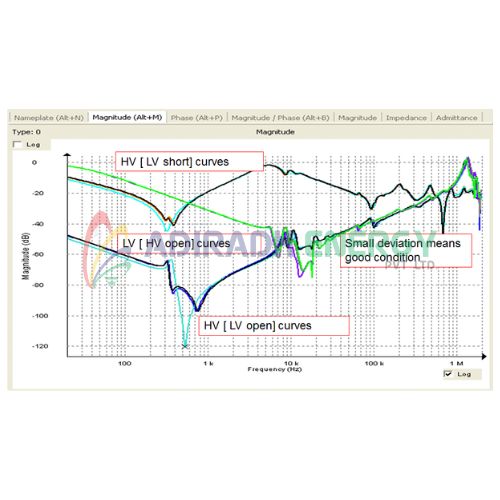

The Sweep Frequency Response Analyzer (SFRA) is a precise diagnostic tool designed to assess the mechanical and electrical integrity of power transformers and other high-voltage equipment. It measures the transformers frequency response over a wide range, detecting issues such as winding movement, core deformation, shorted turns, and mechanical stress that may occur during transportation or operation.

This advanced system provides fast, accurate, and repeatable measurements, ensuring reliable condition assessment and early fault detection. Its user-friendly software enables easy data comparison, analysis, and report generation.

Key Features:

-

Wide frequency range measurement for accurate analysis

-

Detects core and winding movement, deformation, and faults

-

Automatic sweep and comparison with reference results

-

High-resolution digital output and intuitive interface

-

Portable and rugged design suitable for field use

-

USB and PC connectivity for data storage and report generation

-

Compatible with IEC and IEEE standards

Applications:

-

Power and distribution transformers

-

Reactor and instrument transformers

-

On-site commissioning and maintenance

-

Factory acceptance and post-fault analysis

Precision Testing with SFRA

Engineered for critical industrial use, the SFRA provides accurate analysis of transformer winding integrity and core stability. Fabricated from MS, this analog-only device ensures solid construction and reliable performance in demanding environments. Its manual power supply and standard-sized design facilitate straightforward, adaptable testing for various equipment.

Trusted Supplier and Trader in India

We are recognized for supplying quality Sweep Frequency Response Analyzers across India, catering to diverse industrial sectors. Our expertise ensures you receive a robust, dependable SFRA instrument, supported by thorough technical knowledge and prompt service, tailored to your facilitys specific needs.

FAQs of Sweep frequency response analyzer-SFRA:

Q: How is the Sweep Frequency Response Analyzer (SFRA) used in industrial settings?

A: The SFRA is used in industrial environments to assess the mechanical and electrical integrity of transformers and similar equipment. By manually supplying power and using the analog display, operators sweep through a frequency range to analyze response curves, helping detect issues like winding movement or core problems.Q: What materials are used in the construction of the SFRA?

A: Our SFRA is constructed from high-quality MS (Mild Steel), ensuring durability and robustness for long-term industrial use. The device is finished in black for professional appearance and corrosion resistance, adhering to standard sizes for easy integration.Q: When should the Sweep Frequency Response Analyzer be employed?

A: The SFRA should be used during commissioning, after transport, as part of routine maintenance, or whenever mechanical or electrical faults in transformers are suspected. Early diagnosis prevents larger failures and extends the equipments lifespan.Q: Where can I purchase or source the Sweep Frequency Response Analyzer in India?

A: As a leading supplier and trader based in India, we provide SFRA devices to industries across the country. You can contact our sales team for product consultation, quotations, and support tailored to your application.Q: What is the process for conducting a sweep frequency response test with this SFRA?

A: To perform a test, manually connect the SFRA to the equipment under inspection, and use the analog interface to initiate the frequency sweep. Observe the response pattern on the display; deviations indicate potential faults, enabling targeted maintenance decisions.Q: What are the main benefits of using an analog-only SFRA in industrial applications?

A: Analog-only SFRA delivers clear, immediate readings with high reliability, especially in environments where digital displays may be prone to interference. Its simplicity and manual operation also make it easy to maintain and suitable for field use.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in TRANSFORMER AND SUBSTATION TESTING PRODUCTS Category

Hydran M2-X Online Transformer DGA Monitor

Price 2400000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Display Type : Digital Only

Usage : Substation, Utility, Power Plant, Industrial Applications

Size : Standard Sizes

Product Type : Online Transformer DGA Monitor

Transfomer DGA Monitor-InsuLogix G2

Price 2700000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Display Type : Digital Only

Usage : Substation, utility, industrial and power plant applications

CT/PT analyzer-CTPT analyser-CT/VT/CVT analyser

Price 4999099.0 INR / Set

Minimum Order Quantity : 1 Kilograms

Display Type : Analog Only

Usage : Industrial

Size : Standard Sizes

Kelman MINITRANS Portable Transformer Partial Discharge & Condition Monitoring System

Price 2900000.0 INR / Unit

Minimum Order Quantity : 1 Kilograms

Display Type : Digital Only

Usage : Substation, Power Plant, Utility, Industrial

Product Type : Portable Transformer Condition Monitoring System

Send Inquiry

Send Inquiry Send SMS

Send SMS